Purpose

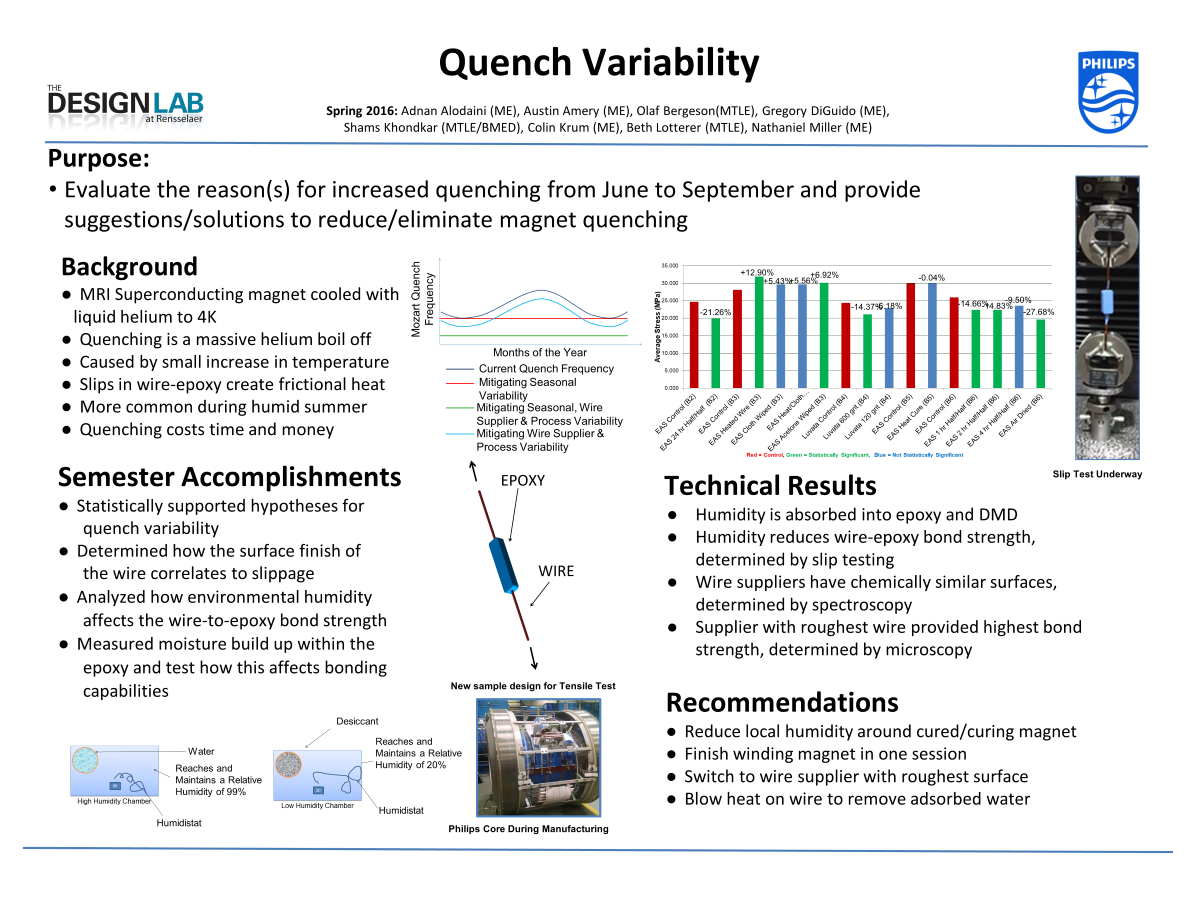

Evaluate the reason(s) for increased quenching from June to September and provide suggestions/solutions to reduce/eliminate magnet quenching during this time period.

Background

- MRI Superconducting magnet cooled with liquid helium to 4K

- Quenching is a massive helium boil off

- Caused by small increase in temperature

- Slips in wire-epoxy create frictional heat

- More common during humid summer

- Quenching costs time and money

Accomplishments

- Statistically supported hypotheses for quench variability

- Determined how the surface finish of the wire correlates to slippage

- Analyzed how environmental humidity affects the wire-to-epoxy bond strength

- Measured moisture build up within the epoxy and test how this affects bonding capabilities

Results

- Humidity is absorbed into epoxy and DMD

- Humidity reduces wire-epoxy bond strength, determined by slip testing

- Wire suppliers have chemically similar surfaces, determined by spectroscopy

- Supplier with roughest wire provided highest bond strength, determined by microscopy

People

Aren Paster

Research Area

Manufacturing, Automation, and Control

Project Type

Manufacturing

Funding Agency/Sponsor

Philips Healthcare