Benefits

Increased blade life & efficiency, safer operation of cold weather turbines; decrease turbine down‐time

Purpose

Investigate the use of microwave de‐icing technology to enhance the performance of wind turbine blades operating in cold environments

Background and Objectives

Spring 2015 Feasible Study

- Deicing requires: surface heat flux of 1.4kW/m2 ,20‐25 minutes of test period and microwave interactive material

- Options: horn antenna and slotted waveguide antenna at 2.45 or 5.8 GHz

Semester Objectives

- Design and test blade‐compatible microwave susceptor coating layer

- Demonstrate effective microwave delivery at 2.45GHz

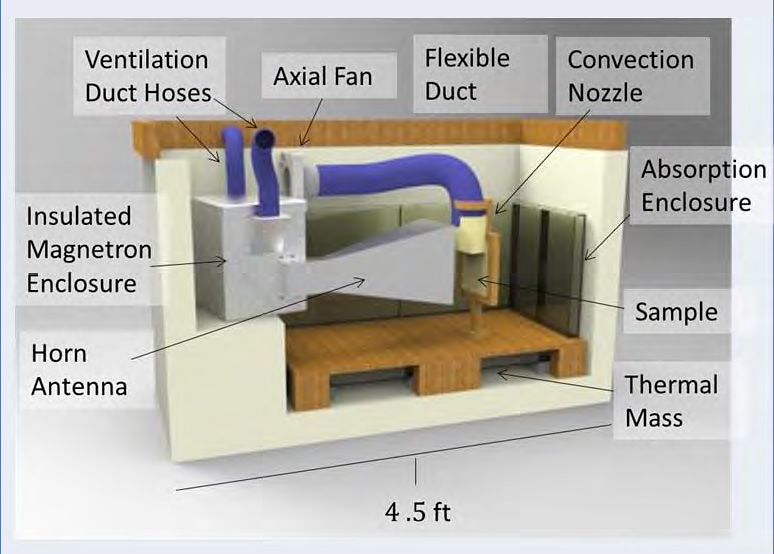

- Build a microwave laboratory test facility and collect deicing data

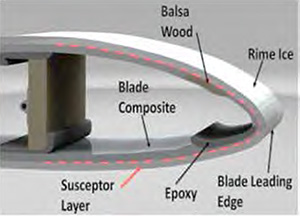

Microwave Absorbing Materials

Problem

- G10/FR4 and Ice are transparent to incident microwave radiation

Solution

- Susceptor coating on blade surface

Requirements

- Maximize conversion of absorbed microwave radiation to heat

- Withstand cyclic thermal stress

- Resistant to UV degradation

Comparison of Coating Methods

| Uniform Surface? | Easy to apply to blade? | Resistant to degradaton? | %Absorption? | Rate of heating | Max temp | |

|---|---|---|---|---|---|---|

| Sputtered AI Film | Yes | No | No | Up to 50% | < 3 min | 200 °C |

| Absorptive Paint | Yes | Yes | Yes | Up to 40% | N/A | 900 °C |

| Dielectric Coating | Yes | Yes | Yes | Up to 99% | < 1 min | 800-950 °C |

Microwave System

Microwave generation:

- Operates at 2.45 GHz

- Microwave Power – ~ 1 kW : 60% efficient

- Cheap – around $50

- Easy to drive – circuits already exist

- Air cooled

Microwave delivery options:

| Type | SWA | Horn Antenna |

|---|---|---|

| Profile | Low (planar form) | High |

| Manufacturing | Good | OK |

| Bandwidth | Narrow | Broad |

| Gain | 15dBi - 20dBi | 15dBi - 30dBi |

| Pattern | Highly directional | Moderately directional |

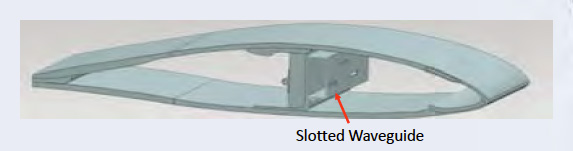

Practical Application

Tower Configuration

- Arrays of SWAs

- 42 SWAs needed for gain of 9 dBi

- Arrays of horns

- 110 horns needed for gain of 10 dBi

- 40 horns needed for gain of15 dBi

Blade Configuration

- SWA incorporated inside the blade

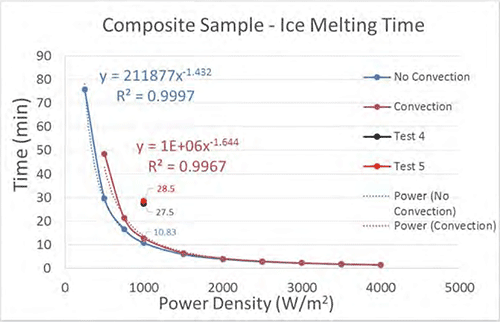

Microwave Deicing Test Results

Results:

- Ice melted within 30 mins

- Test bed ambient temperature remained below freezing

Team Members

- Henry Choi (EE)

- Mengqian Gao (MECL)

- Kevin Hritz (MECL)

- Yuyu Hsueh (EE)

- Ryan Jenkins (MECL)

- Kelly Pifer (MECL)

- Yuhan Shi (EE)

- Alex Wholey (MATL)

Research Area

Energy and the Environment

Project Type

Research

Funding Agency/Sponsor

General Electric