Benefits

Standard maintenance work on gearbox of a wind turbine necessitates the partial disassembly of a large, heavy casting within a small space at top of tower. Carrying the necessary equipment to the top and completing the work requires four technicians to work five 12-14 hour days. Goal of project is to reduce time, reduce cost, and improve safety of workers.

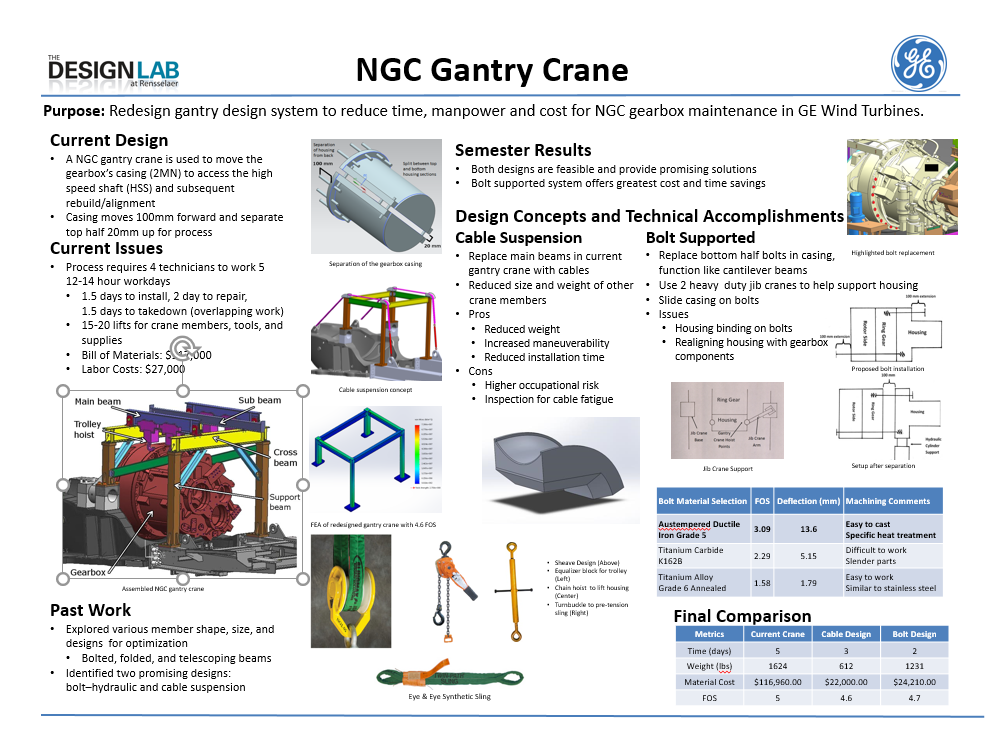

Purpose

Redesign gantry crane system to reduce time, manpower, and cost to complete NGC gearbox maintenance in GE Wind Turbines.

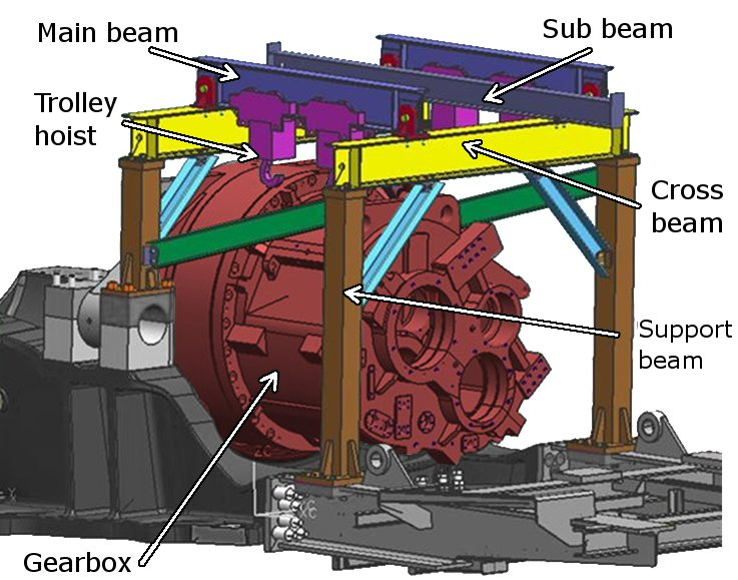

Current Design

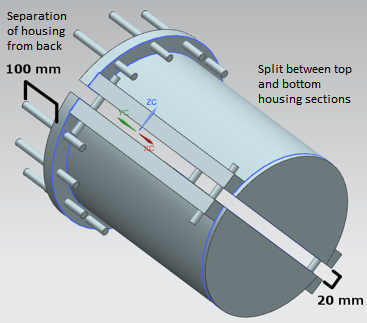

- A NGC gantry crane is used to move the gearbox’s casing (2MN) to access the high speed shaft (HSS) and subsequent rebuild/alignment

- Casing moves 100mm forward and separate top half 20mm up for process

Alternative Approaches

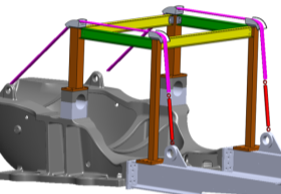

Cable Suspension

- Replace main beams in current gantry crane with cables

- Reduced size and weight of other crane members

- Pros

- Reduced weight

- Increased maneuverability

- Reduced installation time

- Cons

- Higher occupational risk

- Inspection for cable fatigue

Bolt Supported

- Replace bottom half bolts in casing, function like cantilever beams

- Use 2 heavy duty jib cranes to help support housing

- Slide casing on bolts

- Cons

- Housing binding on bolts

- Realigning housing with gearbox components

Conclusions

- Both designs are feasible, safe, and provide promising solutions

- Bolt supported system offers greatest cost and time savings

- 50% manpower reduction

- 75% equipment cost reduction

People

Casey Hoffman

Aren Paster

Research Area

Manufacturing, Automation, and Control

Project Type

Manufacturing

Funding Agency/Sponsor

General Electric